Steel Alloy

AVAILABLE QUANTITIES

100 grams

1 KG

10 KG

100 KG

1.000 KG

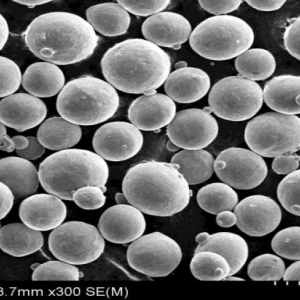

Steel Alloy metal powders

SS316L / SS304L

This Iron-based alloy is the most important and widely used metal in engineering. When compared with the traditional casting forging technology, it has higher strength, excellent high temperature resistance, wear resistance and corrosion resistance. It also has a high dimensional precision and material utilization, which perform well in the aerospace, automobile, machinery manufacturing and other industries.

We can supply all types of stainless steel metal powder, such as 303L / 304L / 316L / 317L / 310 / 303LSC / 304LSC / 316LSC / 410L / 430L / 434L / 420 / 440.

SS17-4PH

17-4PH is prized by designers and manufacturers because of its properties, which allow for the production of reliable and cost effective

fabrication. 17-4PH offers unique properties like corrosion resistance, good mechanical properties and high toughness and strength. All while providing an operating window over 300°C.

18Ni300

18Ni300 is a kind of maraging steel with low carbon content. It has high tensile strength and hardness with excellent weldability and thermoplasticity, specifically used in injection molding, die-casting, functional components and batch mold tools.

H13

H13 mold steel powder can be divided into: cold rolled die steel, hot rolled die steel and plastic die steel. These three types are used for forging, stamping,

cutting, die casting and so on. As a result of a variety of different applications and complex working conditions, it should have high hardness, strength, wear resistance, enough toughness, and high hardenability.

M2

M2 has high toughness, good thermoplasticity, high hardness, wear resistance and thermal hardness. As well, the hardness does not decrease significantly when its temperature reaches 500~600℃. It can cut at a higher speed than low alloy cutting tool steel and is mainly used to manufacture various cutting tools with high cutting speed, heavy load and high working temperature.

Different types of stainless steel metal powder can be used in different production methods:

- 3D Printing – Additive manufacturing

- Composite filling

- Sintering

- Supersonic gas dynamic cold spraying

Main characteristics

- Widely used in many sectors and for many applications, such as food processing equipment, quarrying and water filtration, pressure vessels, storage tank components, heat exchangers, piping systems, flanges, valves, etc.

- Good machinability and weldability

- High corrosion resistance

- High strength

- Good heat resistance

Designation

- UNS: S30403 / S31603

- DIN: –

- GB: –

SS304L

Material composition

SS316L

Material composition

SS17-4PH

Material composition

M2

Material composition

Tapping density = >4.5G/CM³

Bulk density = >4.0G/CM³