Nickel Alloy

AVAILABLE QUANTITIES

100 grams

1 KG

10 KG

100 KG

1.000 KG

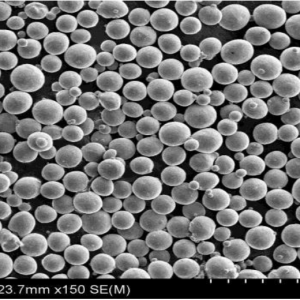

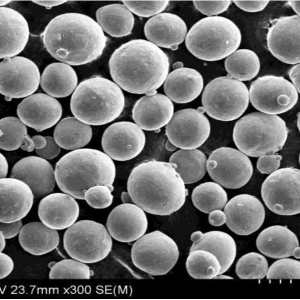

Nickel Alloy metal powders

Inconel 600 / 625 / 718

Inconel alloy refers to a kind of metal materials based on iron, nickel and cobalt, and is a solution strengthened deformed alloy with a service temperature of up to 950℃. It has excellent high-temperature strength, good oxidation resistance and thermal corrosion resistance, good fatigue performance, fracture toughness and other comprehensive properties, and is also known as “superalloy”.

We can supply all types of nickel alloy metal powder, such as inconel 600 / inconel 625 / inconel 718.

Main characteristics

- Widely used in many sectors and for many applications, such as aerospace parts, jet engines, exhaust systems, etc.

- Good toughness and high strength

- Good ductility

- Good resistance to corrosion and high temperature oxidation

- Excellent mechanical properties at high temperature (up to 950°C)

- Excellent creep rupture strength below 700 °C

Designation

- UNS: Inconel 600 / Inconel 625 / Inconel 718

- DIN: F3055 / F3056

- GB: GH4169 / GH3625

Inconel 625

Material composition

Tapping density = >4.5G/CM³

Bulk density = >4.0G/CM³

Inconel 718

Material composition

C = 0.02 – 0.08